HCV Emission Test Facility

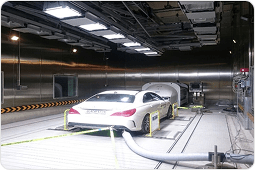

Climatic Vehicle Test Cell (CVTC)

- Climatic Chamber and Low temperature soak room with temperature range from -30°C to 55°C

- Emission Testing for Vehicle up to 3.5 T GVW

- Capability for Type-VI Regulatory Test – Measurement of Cold CO and HC at -7°C

- For Solar Simulation with Radiation area: 7500 mm × 2500 mm

- Chassis Dynamometer with 220 kW Power, Inertia Simulation from 454 to 5448 Kg and Max speed 250 km/h along with exhaust emission sampling and analysis system

- Data Acquisition and Complete Test Cell Automation

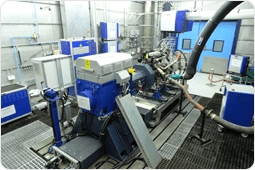

- Mileage Accumulation Chassis Dynamometer (MACD)

- Endurance Testing of 2WD and 4WD Vehicle

- Chassis Dyno with 220 kW Power, Inertia Simulation from 454 to 5448 Kg and Max Speed 250 km/h

- Robot Driver for all Global Driving Cycles for Actuation of Gear, Throttle, Clutch, Brake and Ignition Key

- Automatic Refuelling system to handle liquid fuels like Petrol, Diesel, Ethanol, Methanol and various blends and Gaseous fuels like LPG, CNG and other alternate fuels

- Data Accumulation System with 33 Channel

-

AC ON Testing as per AIS 213 requirements

- Type-VI Test i.e. Measurement of Cold CO and HC at -7°C – Export Homologation / Development Test

- HVAC and Aerothermal validation exercises

- Vehicle calibration on various temperatures and solar load conditions by using PEMS

- Low Temperature Soak Room used for Cold Start ability of Trucks and buses as well as Gensets, 3W and 4W vehicles

- Low Temperature Soak Room utilized for NVH testing of 4W Passenger Car

- EV Charging Facility inside the Chamber (-20°C to +50°C)

Vehicle Test Cell (VTC 1)

- Have capability for Domestic Certification for the BS VI Emission Regulation, along with all capability to suffice WLTP test requirements.

- Export Homologation Testing as per UNECE, EEC Directives and US EPA and Japanese Emission Regulations

- Emission Testing on Vehicles fueled with Liquid fuels such as Diesel, Petrol, Methanol, and their blends Gaseous fuel such as LPG, CNG and it blends with Hydrogen

- Chassis Dyno with 150kW Power and Inertia Simulation up to 5448 Kg and Max Speed 250 Km/h

- Additional Dilution Tunnel for Gasoline Direct Injection Vehicles with PM and PN Measurement

- Test Cell Temperature: 25°C ±5°C, Controllable within 25°C ±1°C, Test Cell Humidity: 9 ±2 g of H2O / Kg dry air, soak room Temperature: Controlled within 23°C ±2°C

- PM Conditioning Chamber with Microbalance having readability of 0.1 Mg and Temperature and Humidity Control

- Opacimeter for Smoke Measurement, Dynamic Fuel flow meter for measurement of continuous fuel flow

- Central Gas handling system for operating and calibration gases

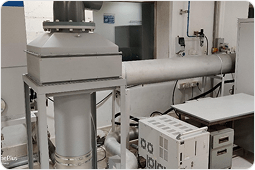

V V-VT SHED for Evaporative Emission Determination

- Capacity to test the Gasoline and Ethanol fueled 2wh, 3wh and 4wh vehicle as per Indian, and all export regulations like Europe, CARB, Brazilian, EPA, Chinese regulations, etc.

- Volume Compensation System: Movable roof with test volume range from 47 cu-m to 54.0 cu-m

- Temperature range: 10°C to 60°C, Controllability: ±0.3°C

- SHED Chamber size: 6500mm(L) × 2600mm(W) × 2500mm(H)

- Independent, sequential and Multiple Canister Loading bench with Auxillary Canister and scale for Breakthrough Test, having feature for Certification and Development Purpose

- Onboard Refuelling Vapour Recovery (ORVR) Test Facility

- Fuel Cart with adjustable fuel Conditioning

- Temperature Range: 10°C to 32°C

- Adjustable flow Rate: 3–12 Gallons per Minute

Vehicle Test Cell 2 (VTC 2) for 2W, 3W, 4W testing up to 1500 Kg Inertia Simulation

- Facility is suitable for development and certification as per Euro-IV, Euro-VI and BS-VI requirements for 2W, 3W and 4W vehicles up to 1500 Kg inertia simulation.

- Certification of 2W vehicles as per US-EPA CFR Title 40, Part 86, Subpart F.

- Export Homologation testing for applicable global regulations.

- 4×2 Chassis dynamometer with dyno power of 87 kW and provision for automatic engaging and disengaging of two rollers in case of 2 wheeler testing.

- Universal chassis dynamometer suitable for testing of 2 Wheeler, 3 Wheeler and 4 Wheeler vehicles.

- Inertia simulation range from 150 to 1500 Kg with maximum speed capability up to 200 km/h.

| Exhaust Gas Analyzer | Regulatory Requirement | Available | Range |

|---|---|---|---|

| CO | Non-dispersive Infra-red (NDIR) | NDIR | 0 to 1000 ppm |

| CO₂ | Non-dispersive Infra-red (NDIR) | NDIR | 0 to 5 % Vol |

| NOx / NO | Chemi-Luminescent (CLA) | CLA | 0 to 500 ppm |

| CH₄ | Flame Ionization Detector (FID) | FID | 0 to 500 ppmC |

| THC | Flame Ionization Detector (FID) | FID | 0 to 500 ppmC |

| Heated THC (Diesel) | Flame Ionization Detector (FID) | FID | 0 to 500 ppmC |

| N₂O | Laser Spectroscopic | — | 0 to 200 ppm |

Mileage Accumulation Chassis Dynamometer (MACD 1 and MACD 2)

|

Other Features

Robot Driver: to run in 2WD and 4WD operation. Robot to deal with

Automatic Refueling System: to handle fuels like petrol, diesel, |

||||||||||||||||

|

|

|

|

| MACD 2 | MACD 1 |

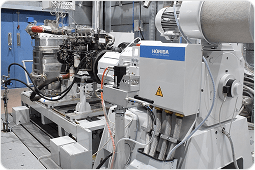

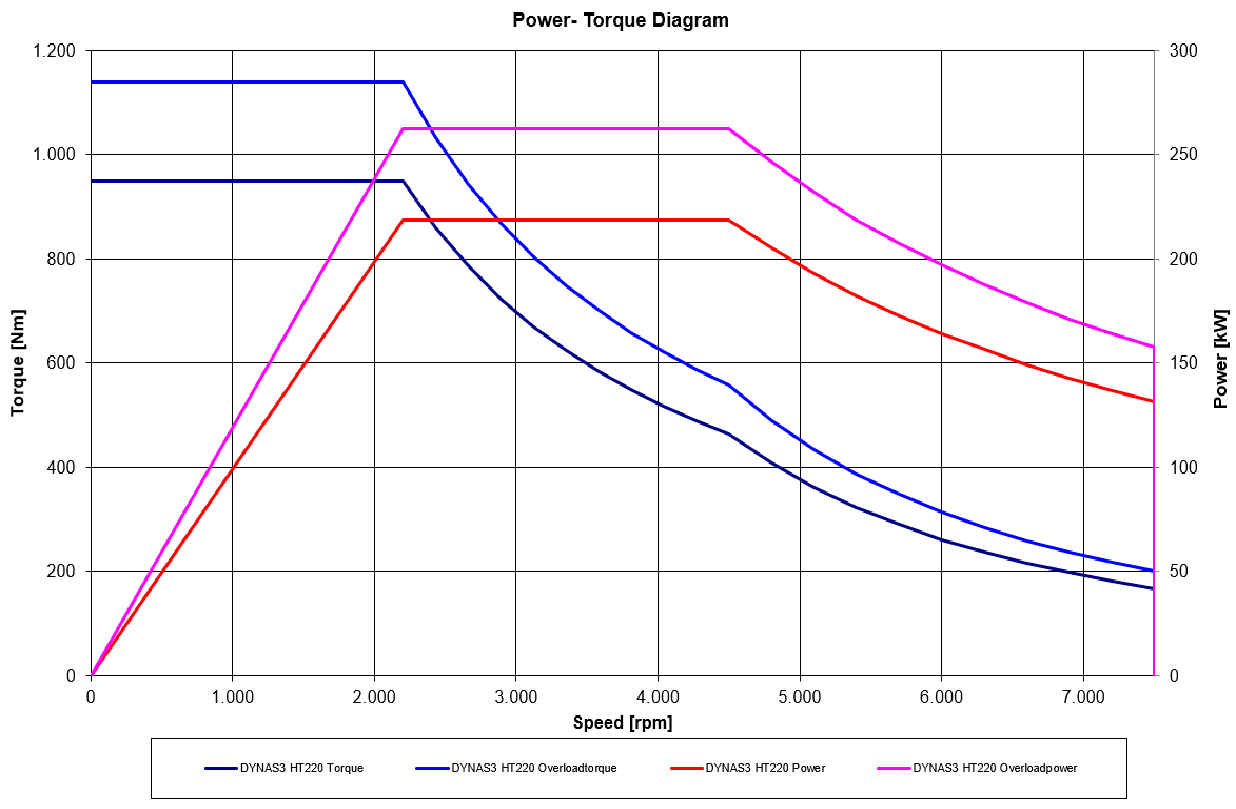

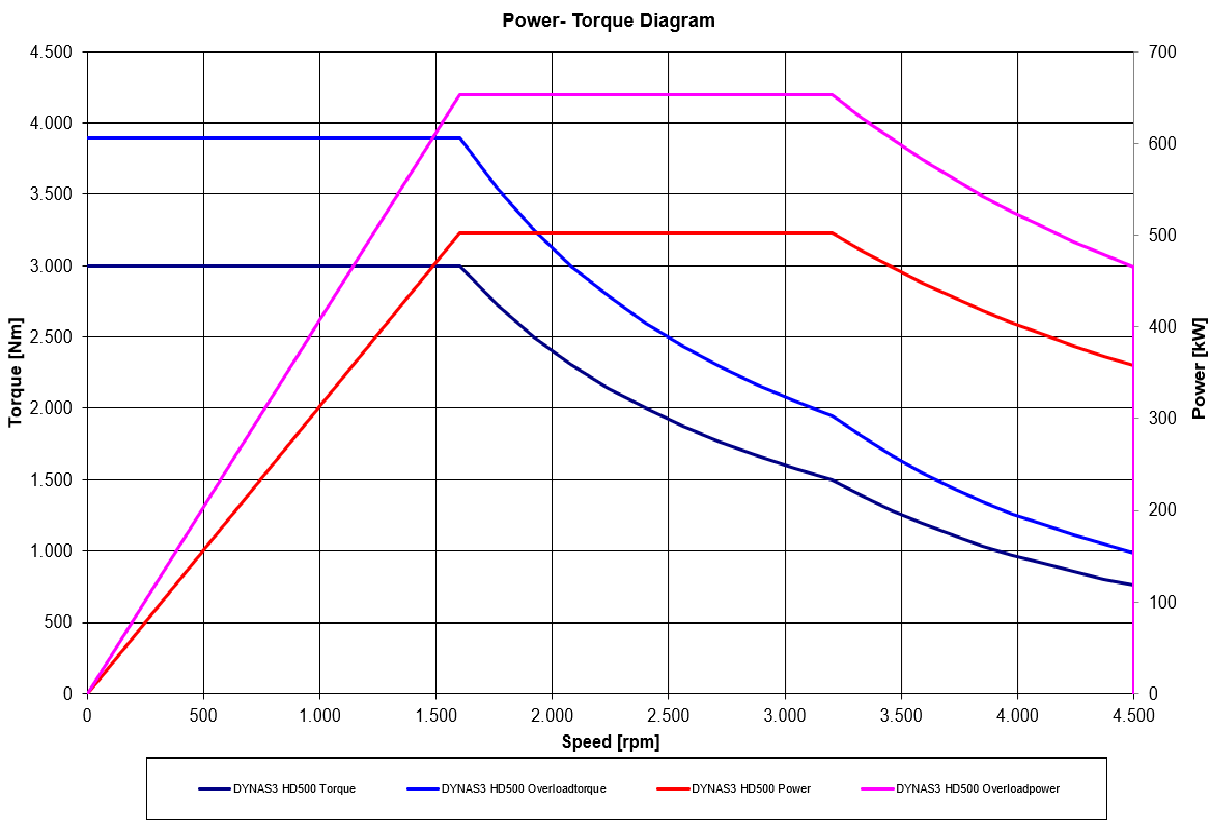

Engine Certification Dynamometer

|

|

|

| Specification | ETC1 | ETC2 |

|---|---|---|

| Dyno Power | 500 kW @ 1600 – 3200 rpm | 220 kW @ 2200 – 4500 rpm |

| Dyno Torque | 3000 Nm | 950 Nm |

| Emission | Pre & Post Analyzer | Pre & Post Analyzer |

| PM & PN | Partial Flow Measurement | Partial Flow Measurement |

| NH3 Measurement | FTIR | FTIR |

- Facility catering to certification and development of Diesel / Gasoline / Biodiesel / CNG / LPG engines.

- Suitability for Automotive BSVI / Euro VI, Tractor / CEV BSVI, BSV and Combined Harvester Emission Certification / Development testing.

- Facility compliance to wide range of regulations such as AIS 137, TAP 115/116, ECE R49 rev.06.

- Unique facility for simulating High Altitude ambient condition of 1600 meters with 82.5 kPa ambient pressure on engine inlet and outlet.

Sealed Housing For Evaporative Determination(SHED)

- Compliance to Indian, European, EPA and CARB Regulations

- Capable of measuring evaporative emission from 2, 3 and 4 Wheeler vehicles

- The 87.48 m3 volume SHED facility has the wide temperature range of 15 oC – 50 oC

- Fully Automated facility.

Engine Dynamometer Test Facilities

- Compliance with BS II, BS III, BS IV, BS IV, Euro IV, Euro V, Euro VI, EPA and future norms

- Evaluation of engine emission (Engine steady state Cycle & Engine Transient cycle), power test, smoke test

- Steady state dynamometer facility is equipped with Engine dynamometer, Raw emission analyzer bench, Partial flow PM sampling system, dynamic fuel meter, fuel and coolant conditioning unit, Smoke meter

- Steady-state dynamometer capacity: 20 kW, 150 kW

- Transient state dynamometer facility is equipped with engine dynamometer, full flow CVS and dilution tunnel system, Dilute emission analyzer bench, Dynamic Fuel meter, fuel and coolant conditioning unit, Smoke meter, FTIR for NH3 measurement, PN measurement system, High altitude simulation up to 5500 feet

- Transient dynamometer capacity: 220kW, 500kW, 250kW