Emission Certification Laboratory

Emission Certification Laboratory

- Type Approval (TA), Conformity of Production (COP), In service conformity (ISE),Real Drive emissions (RDE) & Mileage accumulation durability testing for :

- 2/3 Wheeler, Passenger Cars, Light Commercial Vehicles

- Heavy Commercial Vehicle (HCV) engines, Tractor, Construction Equipment, Stationary and Gen-set engines, On road and off road application vehicles.

- Evaporative emission measurement in SHED facility

- State-of-Art utilities for temperature and humidity control in all test areas,central gas handling system, eco-friendly firefighting system and emergency power back-up

- Accredited and Certified – NABL- ISO / IEC 17025: 2017, ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018, TRIAS 31 – J044GTR002-01 by NTSEL.

Our Capabilities and Competence

- Emission System / Laboratory / Facility approval at Vehicle / Engine Manufactures Place for COP tests

- Certification as per EPA, CARB, European and Japanese standards

- Evaluation of alternative fuel vehicle/engines- CNG, LPG, Hydrogen, Ethanol, Methanol, Bio-diesel

- Development assignment to evaluate Buses and Trucks for pollution control devices for emission, fuel efficiency etc.

- Special assignment on an evaluation of oil/ fuel/additive for performance, emission and fuel consumption

- Study of Particulate matters for toxicity and evaluation of Non-particles

- Ambient air quality Management- Air Quality Monitoring, Emission factor determination and source profile, inventory generation (line/ area/point sources), forecasting studies and health impact assessment

- Formulation of Regulation/ Procedures on Emission and related issue

- Knowledge sharing through workshop/ seminar and special training courses on emission/alternate fuel

- Secretariat for Standing Committee on an implementation of Emission Legislation

- Secretariat for working party on pollution and energy (GRPE) under WP 29

Two Wheeler Emission Test Facility

- Compliance to BSVI, European, EPA Norms, GTR, China, Brazilian, Thailand,Indonesian, and other global Norms

- Equipped with Chassis dynamometer, CVS system, Emission analyzer bench, Weather station

- Fully capable with all the required accuracy of measurement, fully automated test bench with controlled ambient air parameters like humidity and temperature

- Chassis Dyno capacity: Power: 70KW, Inertia Range: 100-550kg, Max Speed: 200kmph

- Impinger system for carbonyl emission measurement from ethanol/methanol-fueled vehicles

Flex Fuel vehicle certification test facility for Two, Three and Small four wheel vehicles.

- Compliance to BSVI, European, EPA Norms, GTR, China, Brazilian, Thailand, Indonesian, and other global Norms

- Equipped with Chassis dynamometer, CVS system with dilution tunnel, Emission analyzer bench, Weather station, 2.5 um PM measurement system

- Equipped with flex fuel vehicle testing facility up to E100, M100 fuelled vehicles .

- To ensure the accuracy of measurement, fully automated test bench with controlled ambient air parameters like humidity and temperature

- Chassis Dyno capacity: Power:50Kw, Inertia range:100-1500 Kg, Max Speed: 200Kmph

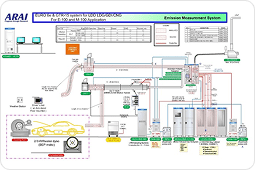

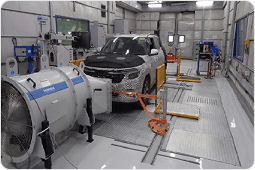

Four Wheeler Emission Test Facility

- Compliance with BS III, BS IV, BS VI, Euro IV, EPA and future norm

- Equipped with 4 X 4 vehicle chassis dynamometer, CVS system with dilution tunnel and latest generation exhaust gas analyser bench with dirty/clean line concept for distinguishing between clean and dirty vehicle during emission measurement

- To ensure accuracy of measurement, fully automated test bench controlled ambient air parameter like humidity and temperature.

- Chassis Dyno capacity: Power: 155kW, Inertia range: 450-4820 Kg.

- Impinger system for carbonyl emission measurement from ethanol/ methanol-fueled vehicles

Mileage Accumulation Chassis Dynamometer (MACD)

| Parameter | Details |

|---|---|

| Make | Burke E. Porter, USA |

| Type | AC Machine (Single Roller) |

| Maximum power | 149 kW absorption / motoring |

| Maximum Speed | 200 km/h |

| Maximum tractive effort | 5844 N |

| Vehicle inertia range | 120 to 5443 Kg. |

| Roller diameter | 1220 mm |

Real Drive Emission testing (RDE)

ECL RDE Capabilities includes:

- 6 nos. of portable emission measurement systems (PEMS)

- Range of different flow meters to cater requirement of each vehicle testing

- System is compliant to RDE package 4 testing

ECL RDE test equipment’s are being used for:

- Light Duty RDE Tests

- HDV PEMS Tests

- Raw Emission Measurement for Engine vehicle Calibration on Chassis Dyno in Different Environmental Conditions

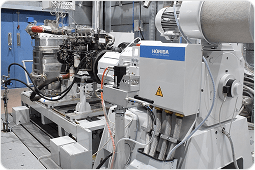

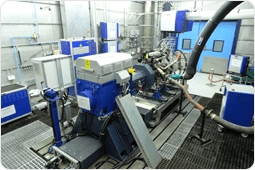

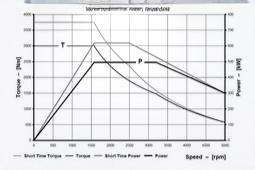

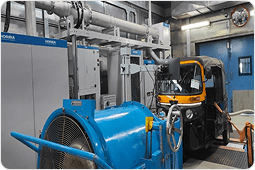

Engine Certification Dynamometer

- Engine certification BSVI, Stage IV and Stage V

- Export Homologation for various automotive and Non Road application,like EURO III, EURO IV, Euro V, Euro VI, Stage IIIA, Stage IIIB,Stage IV, Stage V and EPA Tier 4 interim with Europe and US EPA reference fuel

- Full Throttle Performance checking & Optimization with Conditioned air supply

- Engine Friction Measurement with controlled Oil & Water temperature

- ET & FMTC mapping for Common Rail Engine initial development

- Basic Common Rail Engine ECU mapping

- PreCAT & PostCAT emission measurement

-

High altitude simulation up to 1600 meter with the help of

Exhaust Extraction unit - Vehicle Simulation on Engine Test Bed

| Specification | Cell 3 | Cell 4 | Cell 5 | Cell 6 |

|---|---|---|---|---|

| Dyno Power | 250 kW @ 2000–5000 rpm | 220 kW @ 2200–4500 rpm | 500 kW @ 1600–3200 rpm |

105 kW @ 2000–4400 rpm 20 kW @ 2800–8000 rpm |

| Dyno Torque | 1200 Nm @ upto 2000 rpm | 950 Nm | 3000 Nm |

501 Nm upto 2000 rpm 80 Nm @ 1400–2800 rpm |

| Emission | Post Analyzer | Pre & Post Analyzer | Pre & Post Analyzer | Post Analyzer |

| PM & PN | Partial Flow Measurement | Partial Flow Measurement + CVS | Partial Flow Measurement + CVS | Partial Flow Measurement |

| NH3 Measurement | LDS | FTIR | LDS | LDS |