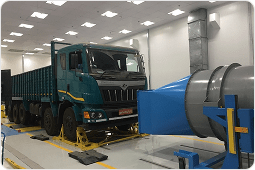

ARAI HTC TEST FACILITY

HCV Emission Test Facility

- Large Roll set with surface Coating with 2.5m (98-inch) diameter. The rolls are manufactured with ASTM- A-516 Grade 70 Carbon steel & Tungsten carbide coating

- Inertia range 3500kg to 60000kg

- Tractive Efforts – 32250N for 3 loadcells & 3 motors of 1500HP.

- Test Speed range 0 to min 160kmph with precision optical encoder (47200ppr)

- Maximum Permissible Axle Load – 20000kg

- Torque & Response time – <100 ms

- Motor base inertia, kg – 8000±10%

- Minimum Acceleration with 60 tonnes full load- 1 m/s2 .

- This dyno can take Tandem Axle vehicle for testing which has distance of 1.3 m to 1.8m in driven axles

- In this facility, all EV-HEV vehicles/ buses, Diesel , CNG, LPG, LNG, flexi fuel etc., development work can be taken to cater todays customer’s need

- In this temperature controlled test cell at ARAI Kothrud, Exhaust gas Emission Measurement system for CO, HC, NOX, CO2, Fuel consumption and PM using PEMS

- Electric Vehicle Range test, energy consumption and various development test can done . Charger for these vehicles is installed in HCV

- A 100kW resistive 2 Nos. load banks was recently added to the setup to increase the test cell’s operating temperature to 50 degrees Celsius. Due to this hot summer trials for Engine calibrations on HCVs can be performed on this chassis dynometer.

- Vehicle position limit switches

- Laser alignment mounting

- Tyre burst protection

- Emergency regenerative braking

- Length:

- Rigid transport : 12m

- Articulated Vehicles: 16m

- Truck Trailer :18m

- 3 Axle Passenger Vehicle: 15m

PEMS Pro-Cart Vehicle

(Mobile Emission Measurement Van & Workstation)

As per regulatory requirements under BSVI norms and upcoming CEV/TREM Stage V standards, real-world emission measurement is critical.The PEMS Pro-Cart is designed to meet this need by enablingReal Drive Emission (RDE) testing andIn-Service Conformity (ISC) checks across diverse terrains and customer sites.

Key Highlights of PEMS Pro-Cart

-

✅ Integrated Mobile Workstation:

Comfortable workspace for engineers and customer representatives with power outlets and AC for optimal conditions. -

✅ On-Site Capability:

Equipped with a 1-ton crane for smooth loading/unloading of PEMS equipment, safe storage for gas cylinders, and ventilation for safety. -

✅ Self-Sufficient Power:

Portable genset and air-conditioning ensure uninterrupted operations at remote locations. -

✅ Versatile Applications:

Ideal for RDE tests on highways, mines, construction sites, and farms for non-road applications.

This innovation will transform field emission testing,offering real-time data monitoring, analysis, and maintenance support at the test site.

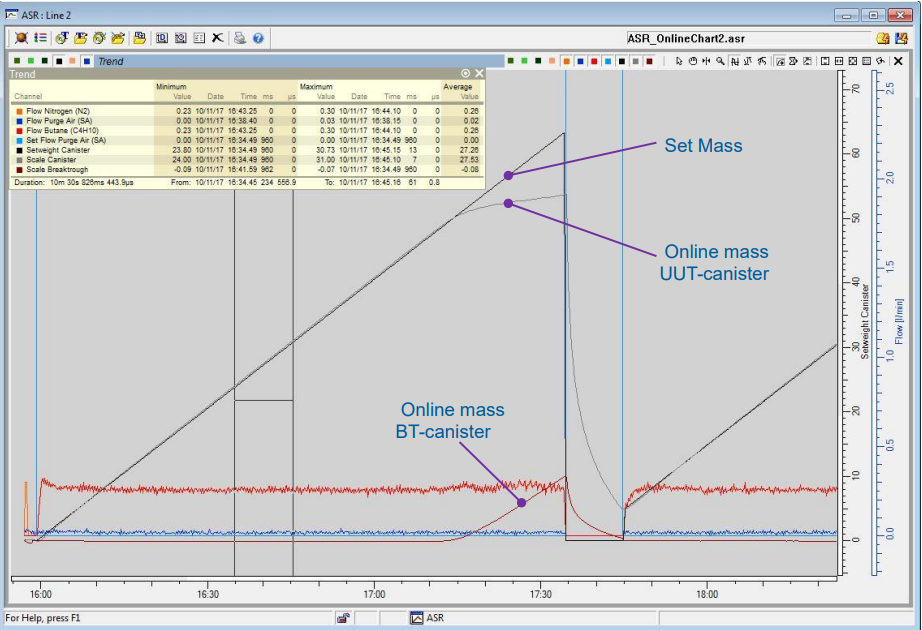

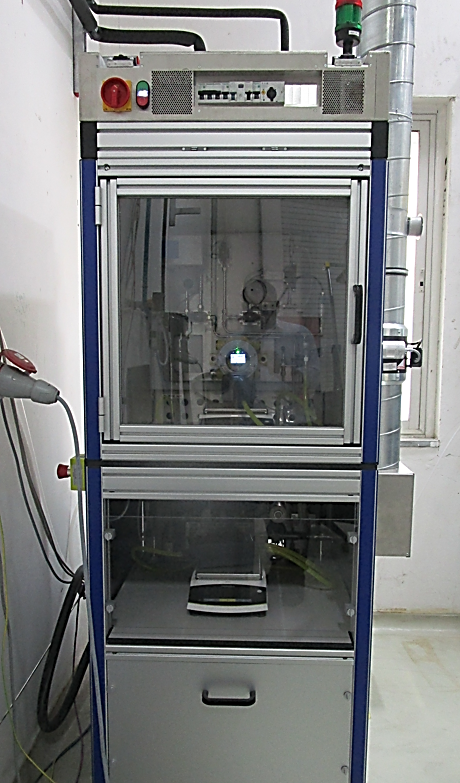

Canister ageing bench – fuel vapour ageing as per AIS 175 WLTP and GTR 19

|

|

|

- Canister loading with fuel vapour and Butane

- Fuel vapour loading rate up to 300 g/h (selectable)

- Butane loading rate up to 220 g/h (selectable)

- Fuel adaptability: Gasoline fuel with Ethanol content up to 85% (E85)

- Operating temperature range: 10°C to 40°C

- Gasoline Density Measurement (GDM) sensor

- UUT weighing scale with weighing capacity of 6.2 kg

- ATEX proof installation

- Online trend data information

- Online 1 Hz data ASCII export

- Combined MS Excel report generation

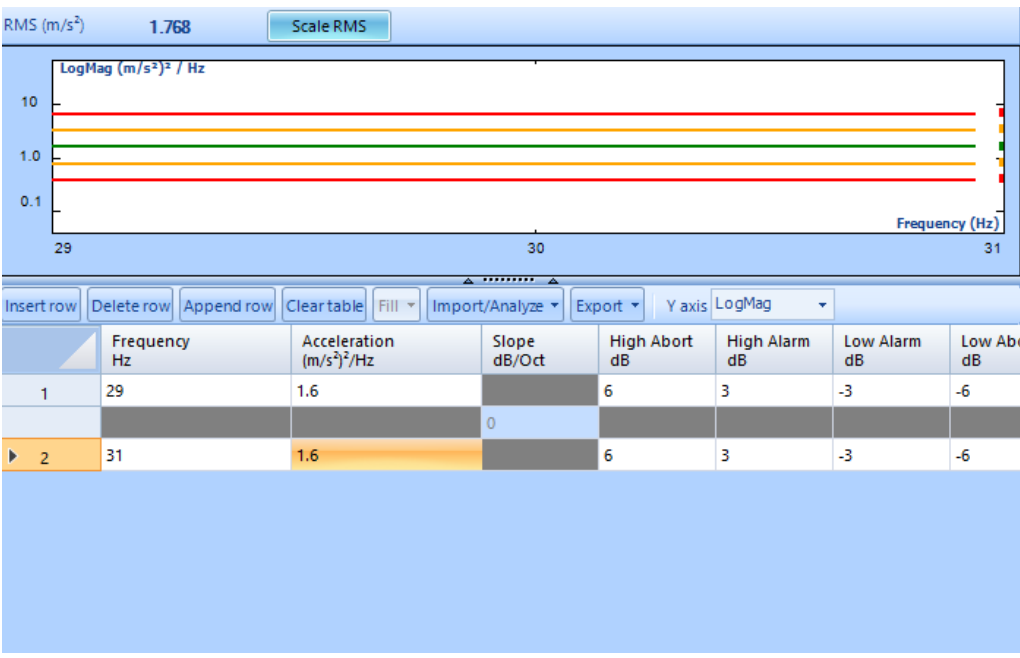

Canister Vibration Ageing Bench

- Sine Force Peak : 2000 kgf

- Maximum velocity : 1.8 m/s

- Frequency: 5 Hz to 2000 Hz

- Shock Test: 4000 kgf

- Displacement: 51mm

- Test Axis: X, Y & Z

| Physical quantity | Profile RMS | Profile expected values | Shaker limits | Expected / Shaker limits |

|---|---|---|---|---|

| Acceleration (m/s²) | 1.768 | 5.303 (Peak) | 1681 (Peak) | 0.3% |

| Velocity (m/s) | 0.009495 | 0.02849 (Peak) | 1.778 (Peak) | 1.6% |

| Displacement (mm) | 0.05044 | 0.3026 (Pk-Pk) | 51 (Pk-Pk) | 0.6% |

| Force (kgf) | 6.309 | 18.93 (Peak) | 2000 (RMS) | 0.3% |